Looking for the best FDM 3D printer under budget? Here are the top things to consider to help you find the perfect one for your needs! In this article, we have covered information about FDM 3d printers, their benefits, drawbacks, and buying guides for choosing the best FDM 3D printer for your requirements.

What is a 3D printer?

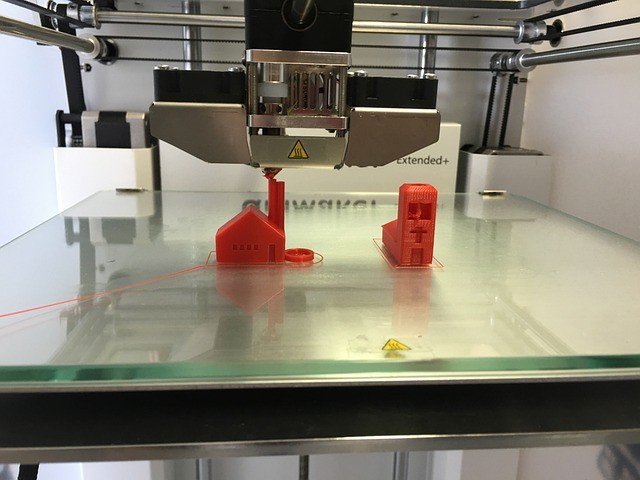

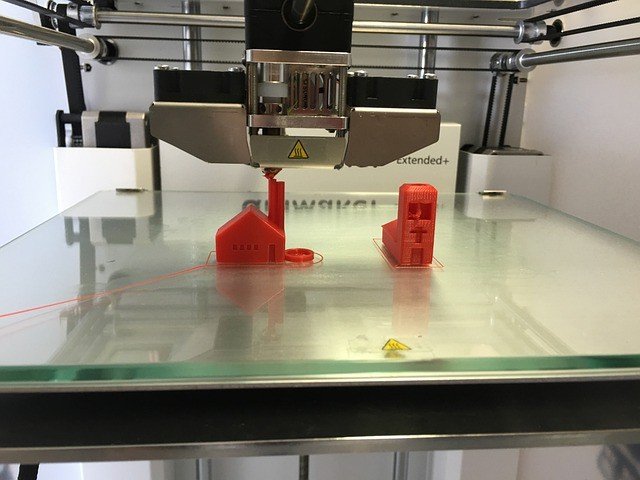

A 3D printer is an additive manufacturing device that creates three-dimensional objects by successively depositing materials under computer control. 3D printers are generally faster, more affordable, and easier to use than other additive manufacturing technologies.

3D printing technology has been around for several decades, but it was only recently that the devices became small enough and affordable enough for consumers to purchase for personal use. In the past few years, 3D printers have become popular among hobbyists, artists, and makers who enjoy using them to create unique or customized items.

If you’re interested in purchasing a 3D printer, there are a few things you should consider before making your decision. This guide will help you understand the different types of 3D printers and what features to look for when choosing one.

Types of 3D printers

FDM 3D Printers

FDM 3D printers are known for their affordability and ease of use. They work by depositing thin layers of plastic onto a build platform, which is then slowly heated and cooled to create the desired three-dimensional shape. FDM 3D printers are ideal for those who are new to 3D printing, as they are relatively simple to set up and use.

SLA 3D Printers

SLA 3D printers are a great option for those looking for a high-quality 3D printer on a budget. One of the main advantages of SLA 3D printers is their high resolutions, which can produce very detailed prints. SLA 3D printers offer large build volumes, which allows you to print larger objects.

One downside of SLA 3D printers is that they tend to be slower than other types of 3D printers. SLA 3D printers require more maintenance than other types of 3D printers, so be sure to factor that into your budget.

DLP 3D Printers

DLP 3D printers use a process called stereolithography, which involves using a light source to cure successive layers of photopolymer resin. This makes for a very precise and smooth finish, but it also means that DLP printers are generally more expensive than FDM printers. If you’re looking for a high-quality 3D printer on a budget, a DLP printer may be the way to go.

DLP 3D printers produce extremely high-quality prints with very fine detail. If you’re looking for the best possible print quality, a DLP printer is probably your best bet. DLP 3D printers are generally slower than FDM printers, due to the need to cure each layer before printing the next one.

SLS 3D Printers

3D printers have come a long way in recent years, and the technology is only getting better. One type of 3D printer that is becoming increasingly popular is the SLS 3D printer. SLS stands for selective laser sintering, and it is a type of additive manufacturing. With SLS, a laser is used to fuse together small particles of powder to create a three-dimensional object.

SLS 3D printers have several advantages over other types of 3D printers. First, they can print with a wider range of materials, including metals and plastics. Second, they are much faster than other types of 3D printers, making them ideal for large-scale production. Third, SLS 3D printers produce very little waste material, as the powder is reused after each print job.

MJF 3D Printers

MJF 3D printers are becoming increasingly popular due to their affordability and quality. MJF 3D printers range in price from around $500 to $3000. Some MJF 3D printers come with built-in slicing software, while others do not. Be sure to check whether the model you’re interested in includes this feature.

MJF 3D printers require more user input than others. If you’re new to 3D printing, look for a model that is simple to set up and use.

PolyJet 3D Printers

If you’re looking for an affordable 3D printer that can produce high-quality results, then a PolyJet 3D printer is a good option to consider. PolyJet 3D printers use an inkjet printing technique that produces very fine details and smooth surfaces. This makes them ideal for printing prototypes or small batches of parts.

Although PolyJet 3D printers are generally more expensive than FDM printers, the cost per print is typically lower. This makes them a good choice for those who need to print large quantities of parts.

Why FDM 3D printers are so popular in the Indian market?

FDM 3D printers have become increasingly popular in the Indian market due to their affordability and ease of use. These printers use a technology called fused deposition modeling (FDM), which extrudes thin layers of melted plastic onto a build platform to create three-dimensional objects.

FDM 3D printers are appealing to consumers and businesses in India for several reasons. First, they are relatively inexpensive compared to other types of 3D printers. Second, they are easy to use, even for those with limited experience with 3D printing technology. Third, FDM printers can be used to create a wide variety of objects, from simple household items to complex engineering prototypes.

There are a few things to keep in mind when choosing an FDM 3D printer for the Indian market. First, consider the price point and compare it to other similar models on the market.

Accessories & Tools required for FDM 3D printers

Following key accessories & tools are required for FDM 3D printers:

Spool of filament

The spool is the container that holds the filament, and it needs to be big enough to hold all of the material you’ll need for your project. If you’re not sure how much filament you’ll need, it’s always better to err on the side of caution and get a bigger spool.

A build plate

A build plate is one of the most important parts of an FDM 3D printer. It is what the printer lays down the filament on to create your object. You want to make sure that the build plate is large enough to accommodate the objects you want to print.

Build plates are typically made from aluminum, glass, or PEI (polyetherimide). Each material has its own advantages and disadvantages. Aluminum build plates are inexpensive and easy to find, but they can be difficult to remove objects from. Glass build plates are smooth and easy to remove objects from, but they can be expensive and fragile.

Slicing software program

When you’re ready to start 3D printing, the first step is finding the right slicing software for your needs. Slicing software takes your 3D model and creates instructions for the printer to follow. It’s important to find a slicing program that is compatible with your 3D printer and has all the features you need. Here are some things to consider when choosing a slicing program:

Look for a slicing program that is easy to use and understand. The last thing you want is to be frustrated with your software every time you try to print something.

Make sure the slicing program has all the features you need, such as support for different types of printers and materials. Some programs also offer additional features like STL editing and repair, which can come in handy. Ultimaker Cura is one of the most popular 3D printing software.

If you are looking for a cloud-based platform that integrates a slicing app but also other features essential for 3D printing, 3DPrinterOS can be the best choice.

How does an FDM 3D printing work?

Fused deposition modeling (FDM) is one of the most popular methods for 3D printing. It works by extruding melted plastic filament through a nozzle to build up layers of an object. An FDM 3D printer typically has two nozzles: one for the model material and one for the support material.

The model material is typically thermoplastic, such as ABS or PLA. The filament is fed into the extrusion head, where it is heated to its melting point and then extruded through the nozzle. The molten plastic cools quickly and solidifies as it hits the build platform, forming a layer of the object.

The support material is typically a different type of thermoplastic that has a lower melting point than the model material. This ensures that the support material can be easily removed from the finished object.

The following steps are involved in the FDM 3D printing process:

Preparing the model: STL file and slicing

Preparing the STL file is one of the most important steps in 3D printing. It is important to make sure that the file is correctly oriented and scaled before slicing. Slicing is the process of converting the 3D model into a pattern that can be printed by the 3D printer. There are many software programs available for slicing, and it is important to choose one that is compatible with your 3D printer.

Once the STL file is prepared, it is time to slice it. There are many software programs available for slicing, and it is important to choose one that is compatible with your 3D printer. Some of the most popular slicing software programs include Cura, Simplify3D, and Slic3r. Once you have chosen a slicing program, you will need to select the settings that are appropriate for your model and your printer.

Choose and Load the filament

You need to have the proper filament loaded into your printer. While there are many different types of filament available on the market, not all of them are compatible with every type of 3D printer. In order to choose the right filament for your machine, you need to take into account the specific capabilities of your printer. For example, some filaments require a higher temperature in order to melt properly, while others may not be able to produce very fine details.

Once you have selected the appropriate filament for your printer, it’s time to load it into the machine. Most 3D printers have a spool holder that holds the filament in place while it is being fed into the extruder. In order to load the filament, simply thread it through the guide tube and into the loading port of your extruder.

Printing the model: layer by layer

As additive manufacturing technology has become more prevalent, the price of 3D printers has fallen, making them more accessible to consumers and small businesses. Fused deposition modeling (FDM) is one of the most popular 3D printing technologies due to its affordability and ease of use.

FDM 3D printers work by layering thin layers of plastic filament on top of each other to create a three-dimensional object. The plastic filament is fed through a heated extruder head, which melts the plastic and deposits it in thin layers onto the build platform. The extruder head moves back and forth across the build platform, depositing melted plastic in a pre-determined pattern. As each layer is deposited, the build platform lowers slightly so that the next layer can be deposited on top of the previous one. This process continues until the object is complete.

Post-processing: removing supports and finishing

After your 3D model is printed, you’ll need to remove the supports and finish the surface. This can be done with a variety of tools, depending on the material. For PLA, you can use a sharp knife or hobbyist sandpaper. For ABS, you may need to use acetone vapor to smooth the surface.

Once the supports are removed and the surface is finished, your model is ready to display or use as intended. Congratulations on completing your print!

Things to consider before buying a 3D printer

There are a few things you should consider before buying a 3D printer.

Price

If you want to buy a 3D printer, you need to consider the price range. There are many affordable options available, but the price can be a major factor when deciding which one is right for you.

The least expensive 3D printers are typically around 16k. These machines are often used for personal or home use and have lower resolutions than more expensive models. If you’re looking for a machine that can produce high-quality prints, you’ll need to spend more money. Higher-end printers can cost upwards of 2 lakh.

When choosing a 3D printer, it’s important to consider your budget and what you plan to use the machine for. If you only need it for occasional projects, a less expensive model may suffice. However, if you plan on using it frequently or for professional purposes, it’s worth investing in a higher-quality machine.

Ease of use

Many 3D printers on the market are very user-friendly, but some can be quite complicated to operate. If you’re not familiar with 3D printing technology, it’s important to choose a printer that is easy to use.

Most consumer-grade 3D printers are fairly easy to use, but there are still some things you need to know before you can get started. First, you’ll need to choose the right type of filament for your printer. There are many different types of filament available, and each one has its own specific purpose. Once you’ve selected the right filament, you’ll need to load it into your printer. Most printers have an enclosed filament chamber that helps to keep the filament clean and free from dust.

Reliability

There are a few things you should take into account when looking for a reliable FDM 3D printer. First, consider the build quality of the printer. A well-built machine is more likely to be reliable than one that is cheaply made. Second, look at the reviews of the printer you are considering. See what other users have to say about its reliability. Finally, ask around. Talk to people who have experience with 3D printing and see if they have any recommendations for a reliable machine.

Automatic bed leveling

Consider when purchasing a printer whether or not the machine has automatic bed leveling. This nifty little feature can be a game changer when it comes to the success and quality of your prints.

For those who are unfamiliar, automatic bed leveling is a process that uses sensors to detect irregularities in the print surface and adjust accordingly. This means that you won’t have to waste time or material manually leveling your bed, which can be a tedious and frustrating task.

Heated build plate

3D printers have come a long way in recent years, and one of the most popular features on high-end machines is a heated build plate. This component helps to prevent warping and curling of large prints, and can also be used to adhere multiple materials together during a single print job.

Consider whether or not you need a heated build plate. If you’re planning on printing large or complex objects, it’s definitely worth the investment. However, if you only intend to use your 3D printer for smaller projects, you can probably get away with a less expensive machine that doesn’t have this feature.

Print Quality

Print quality is often one of the most important factors. After all, what’s the point of owning a 3D printer if the prints are low quality?

The higher the resolution, the finer the detail that can be printed. Some materials produce better results than others – for example, ABS plastic is known for its smooth surface and high level of detail.

It’s worth considering the type of 3D printer you’re using. FDM (fused deposition modeling) printers are generally considered to produce lower-quality prints than SLA (stereolithography) or SLS (selective laser sintering) printers.

Build volume

Build volume is the maximum size of an object that can be printed by a 3D printer. If you are looking to print large objects, you will need a printer with a large build volume. However, if you only need to print small objects, you can save money by choosing a printer with a smaller build volume.

Support

It is important to consider the level of support that is available. Many manufacturers offer great customer support, but there are also a number of independent support forums and websites that can be very helpful.

If you are new to 3D printing, it is definitely worth considering a model that comes with good customer support. Even if you are experienced, there may be times when you need some help troubleshooting or understanding a feature.

There are also a number of online support resources that can be very helpful. These forums and websites are usually filled with experienced users who are happy to help others. They can be a great place to get advice and tips on using your 3D printer.

The Filament Materials Used in FDM 3D Printing

FDM 3D printers work by depositing layers of melted plastic filament on top of each other to create a three-dimensional object. The most common type of plastic used in FDM 3D printing is acrylonitrile butadiene styrene (ABS), but other plastics such as polylactic acid (PLA), and polycarbonate (PC) can also be used.

The choice of material for an FDM 3D print job will depend on the properties required of the finished product.

Acrylonitrile butadiene styrene (ABS)

ABS plastic is a strong, durable material that can withstand heavy use. This makes it an ideal choice for functional parts that need to be able to withstand wear and tear. ABS is also resistant to chemicals and heat, making it ideal for applications where these properties are important.

Polylactic acid (PLA)

PLA is a great choice for those looking for an eco-friendly option as it is biodegradable. It can be used for both prototypes and end-use parts, making it a versatile material. One downside of PLA is that it does not stand up well to heat, so it is not ideal for applications where high temperatures are a concern.

ABS vs PLA

ABS is stronger and more heat-resistant than PLA. However, it’s also more difficult to print with, so it’s not ideal for beginners. PLA is easier to use and produces fewer odors when printing, but it’s not as strong or durable as ABS.

If you’re just starting out, we recommend choosing PLA filament. Once you get more experience, you can experiment with different types of filament to see what works best for your needs.

Polycarbonate (PC)

Polycarbonate is a clear plastic that is often used to create transparent or translucent objects. It is one of the most popular materials for 3D printing due to its durability and versatility. When choosing a 3D printer, it is important to consider the type of polycarbonate that is best suited for your needs.

There are two main types of polycarbonate: extruded and cast. Extruded polycarbonate is cheaper and easier to work with, but it is not as strong as cast polycarbonate. Cast polycarbonate is more expensive, but it is much stronger and more durable. It is the preferred material for applications where strength and durability are required, such as in medical devices or industrial components.

The Benefits of FDM 3D Printing

Greater control over the printing process

FDM 3D printing offers users greater control over the printing process than other methods, allowing for more precise prints. This is due to the fact that the printer lays down thin layers of material on top of each other, allowing for very precise control over the thickness of each layer. FDM 3D printers have the ability to produce complex shapes and structures, as well as the ability to print with a wide variety of materials.

Versatility

It allows users to create products with different functions and appearances. For example, you can use FDM 3D printing to create a product that is both durable and visually appealing. FDM 3D printers is that they can be used to create custom products. Whether you need a custom-sized replacement part or a one-of-a-kind piece of art, an FDM 3D printer can help you create it.

Increased durability

FDM 3d printer is more durable than other types of 3D printing. This means that it can withstand more wear and tear, and last longer overall. Additionally, FDM 3D printing is less likely to break or be damaged in transit. This makes it ideal for businesses or individuals who need to transport their prints frequently

Faster production times than traditional methods

FDM 3D printers are able to print at speeds up to 10 times faster than traditional methods, making them ideal for businesses that need to produce large quantities of parts or products quickly. In addition, FDM printers can print with a variety of materials, including plastics, metals, and composites, giving businesses the ability to create products with different properties and functions.

Lower costs

FDM 3D printing is the lower cost. The technology is less expensive than other types of 3D printing and the materials are also relatively inexpensive. Additionally, FDM 3D printers are often smaller and more compact than other types of 3D printers, making them more affordable for home use.

The Drawbacks of FDM 3D Printing

Not as accurate, lower resolution.

When looking for a lower-priced 3D printer, it is important to consider the accuracy and resolution that the machine is capable of. In general, FDM 3D printers are not as accurate as higher-priced models and have a lower resolution. This means that they are not able to produce as fine a print. However, they can still be used to create functional prototypes and parts.

The slow speed as compared to other 3D printers

One of the things to consider before purchasing an FDM 3D printer is its slow speed. It’s important to know that FDM 3D printers are generally much slower than other types of 3D printers, so if speed is a priority, this may not be the right technology for you.

The poor quality of FDM 3D prints

One of the biggest drawbacks of FDM 3D printers is the poor quality of the prints. They simply aren’t as strong as those produced by other methods, such as SLA or SLS. This can be a big problem if you’re looking to produce functional parts or prototypes.

FDM 3D printers can be quite noisy.

FDM 3D printers can be quite noisy. If you are looking for a printer that is quiet, you may want to consider another type of printer. However, if you are looking for a printer that is affordable and prints well, an FDM 3D printer may be a good option for you.

The dangers of inhaling fumes from melting plastic

These fumes can be extremely harmful to your health and can cause serious respiratory problems. Inhaling even small amounts of these fumes can lead to headaches, dizziness, and nausea. In some cases, it can even cause seizures or unconsciousness. Be sure to research the safety features and take precautions to avoid inhaling dangerous fumes.

Conclusion

3D printers are becoming increasingly popular as they offer a versatile way to create three-dimensional objects. They are now being used in a variety of industries, from manufacturing to architecture. FDM 3D printers are the most common type of 3D printer, and there are many different models available on the market.

If you are looking for the best FDM 3D printer under budget, there are several things to consider. First, what is your budget? Second, what are your needs and wants? Third, what is your level of experience? Fourth, what is the quality of the printer? Fifth, how easy is it to use? All of these factors will help you decide which printer is best for you.

We hope that this article answers your questions, and now you can make a decision to buy the best FDM 3d printer for your needs. Good Luck.!!